Machining is a broad term encompassing the manufacturing processes that use machine tools to remove layers of material from a workpiece to produce the desired part or product. It can be categorized into numerous classifications, such as manual vs. CNC, three-axis vs. five-axis, and vertical vs. horizontal. Each process variant offers unique advantages and disadvantages that make it suitable for different manufacturing projects. Below, we focus on vertical machining.

What Is VMC Machining?

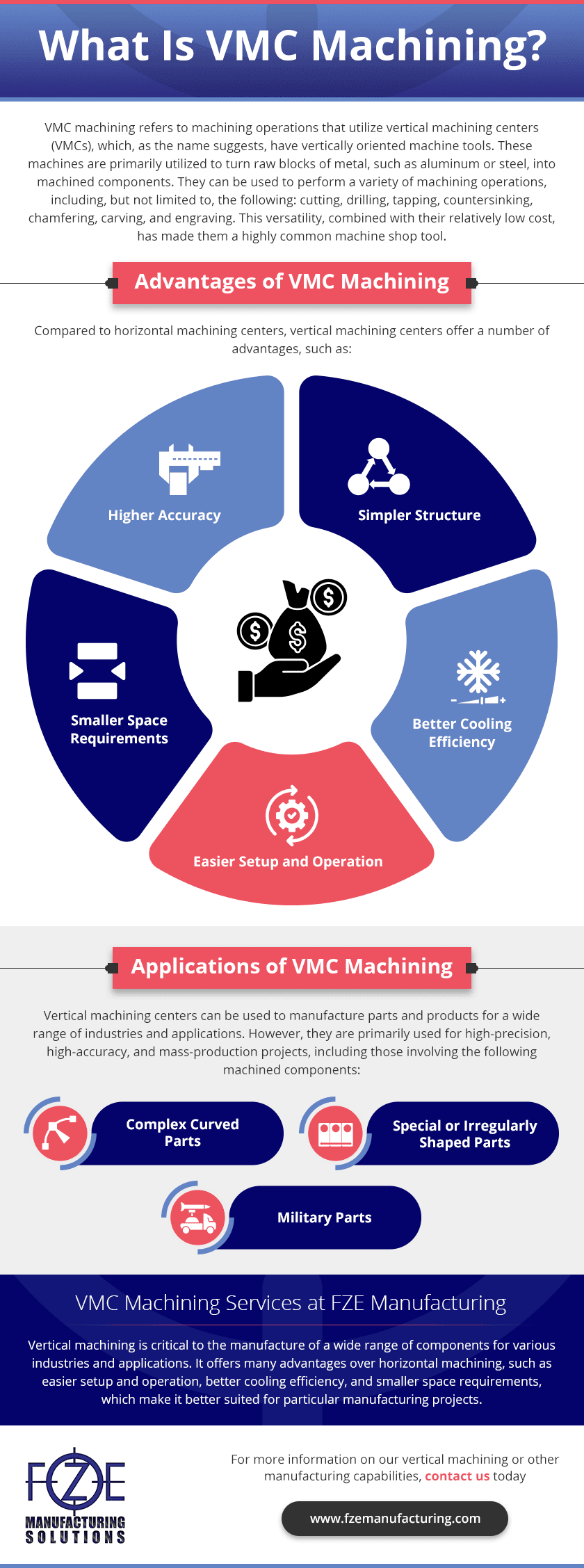

VMC machining refers to machining operations that utilize vertical machining centers (VMCs), which, as the name suggests, have vertically oriented cutting tools.

These machines are primarily utilized to machine and mill raw blocks of metal, such as aluminum, brass, alloy & carbon steel or stainless steel, into accurate machined components. They can be used to perform a variety of machining operations, including, but not limited to, the following: cutting, face milling, drilling, tapping, reaming, boring, countersinking, chamfering, carving, and engraving. This versatility, combined with their ease of use and relatively low cost, has made them a highly common machine shop tool.

The Difference Between CNC and VMC Machining

CNC (Computer Numerical Control) and VMC (Vertical Machining Center) represent different aspects of machining technology.

CNC is a broad category of machines and tools that are operated by computers through programmed commands. It includes various types of machines, including lathes, mills, routers, and grinders, each capable of performing different tasks such as cutting, drilling, and face milling. The key feature of CNC machines is their ability to automate and precisely control these tasks via computer programming and advanced tool selection.

A VMC is a specific type of CNC machine designed primarily for vertical drilling, tapping and milling operations. In a VMC, the spindle with cutting tools are oriented vertically in the Z-Axis and the workpiece is mounted on a table that moves in the X and Y axis. This configuration allows for high-precision drilling, tapping, reaming, boring, milling, etc. VMCs are particularly suited for manufacturing complex parts with detailed features and are widely used in industries such as automotive and aerospace. While CNC technology applies to a variety of machines, a VMC refers specifically to those with vertical spindle setups designed for detailed milling tasks.

Advantages of VMC Machining

Compared to horizontal machining centers, vertical machining centers offer a number of advantages, such as:

- Simpler structure. The simple structure of VMCs makes it easy to clamp the workpiece in the necessary flat position.

- Better cooling efficiency. Gravity works with the VMC design. Coolant sprayed at the top of the cutting tool and workpiece trickles down to cool and rinse the rest of the target.

- Easier setup and operation. VMCs have a wide field of vision, enabling operators to observe the operations and, if needed, make modifications to resolve any issues.

- Smaller space requirements. The vertical design takes up less floor space than a horizontal design.

- High accuracy. VMCs can produce complex shapes and structures with a high degree of accuracy.

Applications of VMC Machining

Vertical machining centers can be used to manufacture parts and products for a wide range of industries and applications. However, they are primarily used for high-precision, high-accuracy, and mass-production projects, including those involving the following machined components:

- Complex curved parts. Examples of parts with complex curves include cams, impellers, and propellers. While these parts are difficult to manufacture with precision and accuracy using conventional machining methods, a multi-axis VMC with CNC technology can produce them easily and quickly.

- Special or irregularly shaped parts. Examples of parts with irregular or special shapes include brackets and bases. These components often have highly complex designs, which are hard to produce using other manufacturing methods but easy to produce using VMCs with automatic machining capabilities.

- Military parts. The military industry is subjected to a variety of standards that dictate how a part can be designed and built. The accuracy and precision of VMCs ensure the machined components produced fully meet the necessary application and industry specifications.

VMC Machining Services at FZE Manufacturing

Vertical machining is critical to the manufacture of a wide range of components for various industries and applications. It offers many advantages over horizontal machining, such as easier setup and operation, better cooling efficiency, and smaller space requirements, which make it better suited for particular manufacturing projects.

Looking for a vertical machining service provider for your next manufacturing project? The experts at FZE Manufacturing have got you covered! We are a full-service manufacturing and machine shop offering a broad selection of machining capabilities. From VMC machining to HMC machining to Swiss machining, we utilize our extensive manufacturing experience and expertise to produce high-quality machined parts and products.

For more information on our vertical machining or other manufacturing capabilities, contact us today. To discuss your machining requirements with one of our team members, request a quote.