Stainless Steel Electropolishing Services

Electropolishing, also called electrochemical polishing, anodic polishing, or electrolytic polishing, is best understood as the reverse of electroplating—i.e., it is an electrolytic finishing process that removes the surface layers of metal (most commonly stainless steel). Compared to mechanical polishing techniques, the method achieves superior surface finishes with greater corrosion resistance and durability. It also has the added benefit of being a more environmentally friendly process, as it does not use harsh chemicals or create hazardous waste. We provide high-quality stainless steel electropolishing services for a wide range of industries, including medical, automotive, aerospace, and more.

Get In Touch Today

Fill out the form below to start a conversation

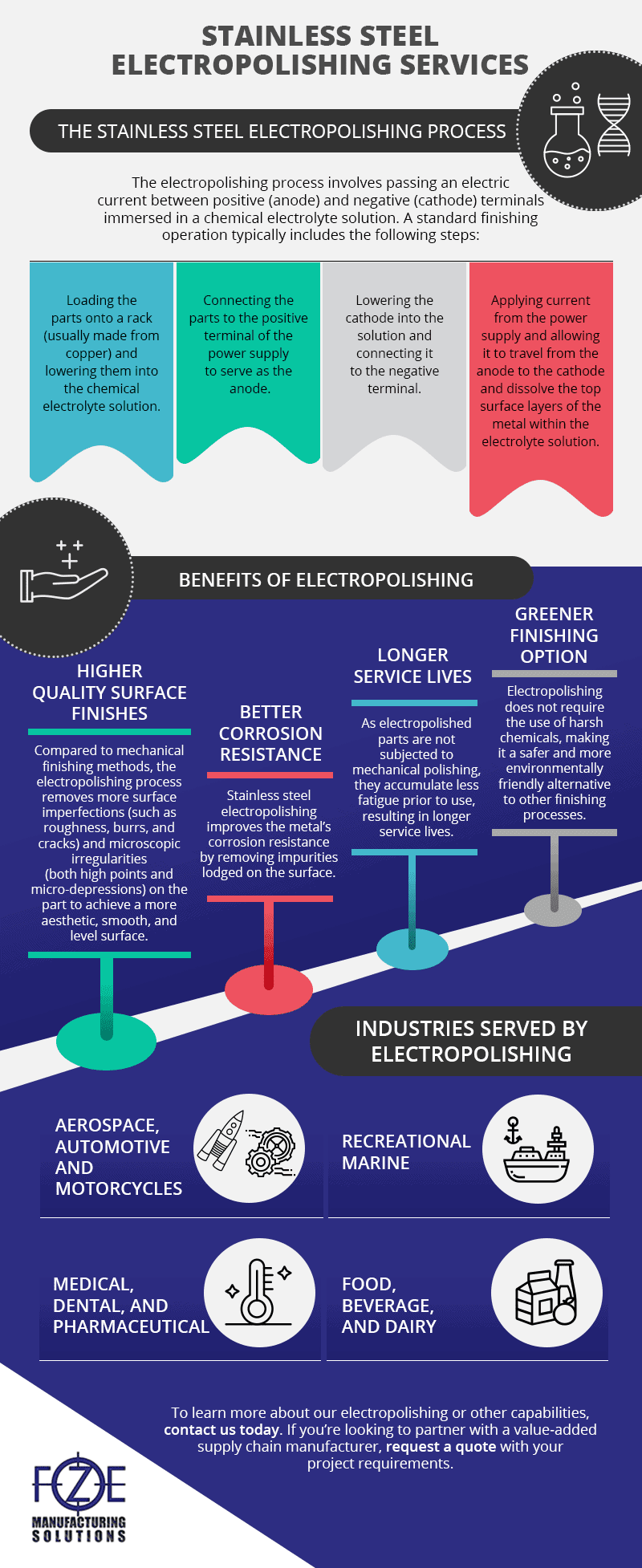

The Electropolishing Stainless Steel Process

The electropolishing stainless steel process involves passing an electric current between positive (anode) and negative (cathode) terminals immersed in a chemical electrolyte solution. A standard finishing operation typically includes the following steps:

- Loading the parts onto a rack (usually made from copper) and lowering them into the chemical electrolyte solution

- Connecting the parts to the positive terminal of the power supply to serve as the anode

- Lowering the cathode into the solution and connecting it to the negative terminal

- Applying current from the power supply and allowing it to travel from the anode to the cathode and dissolve the top surface layers of the metal within the electrolyte solution

The longer the stainless steel part is subjected to the electropolishing stainless steel process, the greater the amount of material removed from its surface. We can control the amount of material removed by adjusting the duration and intensity of the current, as well as the composition of the electrolyte solution. With these variables, we can achieve a wide range of surface finishes, from smooth and shiny to matte. At FZE Manufacturing Solutions, we have the capability to achieve finishes as low as 5 micro inches Ra, making our electropolishing stainless steel services perfect for medical and food-grade applications.

Benefits of Electropolishing

Electropolishing Services provides several benefits to metal parts, including:

HIGHER QUALITY SURFACE FINISHES

Compared to mechanical finishing methods, the electropolishing stainless steel process removes more surface imperfections (such as roughness, burrs, and cracks) and microscopic irregularities (both high points and micro-depressions) on the part to achieve a more aesthetic, smooth, and level surface. This results in a brighter and more reflective finish, increasing the visual appeal of the part.

BETTER CORROSION RESISTANCE

Electropolishing stainless steel improves the metal’s corrosion resistance by removing impurities lodged on the surface. This makes the steel less prone to pitting, crevice corrosion, and stress corrosion cracking. The process also helps eliminate surface contaminants that can lead to bacterial growth or product contamination.

LONGER SERVICE LIVES

As electropolished parts are not subjected to mechanical polishing, they accumulate less fatigue prior to use, resulting in longer service lives. Stainless steel, in particular, has a high fatigue limit and is well-suited for use in environments where corrosion resistance and durability are crucial.

GREENER FINISHING OPTION

Electropolishing does not require the use of harsh chemicals, making it a safer and more environmentally friendly alternative to other finishing processes. The electrolyte solution used in electropolishing can be reused, minimizing waste and reducing the overall environmental impact of the process. The use of electricity in the process also means that it consumes less energy compared to other mechanical polishing methods.

Industries Served by Electropolishing

The electropolishing stainless steel process is suitable for finishing a wide range of materials. In addition to stainless steel, companies use the process to finish aluminum, brass, copper, nickel, titanium, and many other metals and alloys. Some of the industries that use electropolishing services are:

- Aerospace, Automotive and Motorcycles. As electropolishing stainless steel achieves a more pleasing and longer-lasting finish than chrome plating, it is used in the manufacture of parts for airplanes, motorcycles, automobiles, and trucks.

- Recreational Marine. Recreational boats, motors and the related heavy-duty components are often made from Stainless Steel. Properly preparing and Electropolishing these components creates a long-lasting shine and luster requiring little maintenance.

- Medical, dental, and pharmaceutical. These industries use electropolishing for manufacturing sanitary and corrosion resistant instruments.

- Food, beverage, and dairy. Electropolishing stainless steel facilitates the sterilization of tools and equipment used in these industries with ongoing effective sanitation before each use.

- Manufacturers of household appliances use electropolishing to improve the durability and aesthetic appeal of their products.

Electropolishing Services From FZE Manufacturing

For over four decades, FZE Manufacturing has machined and manufactured parts, components, and end products for customers across a broad range of industries, including:

- Agriculture

- Firearms

- Firefighting and Safety Equipment

- Lawn and Turf Care

- Recreational Marine

- Metrology

- Oil and Gas

As a full-service machining and manufacturing service provider, we provide customers with end-to-end solutions from initial design to on-time delivery of a finished part or product. In addition to our machining, manufacturing, and finishing capabilities, we offer the following services:

- Assembly and kitting

- Design assistance

- Inspection, including visual inspection, CMM, and optical monitoring

- Inventory management

- JIT manufacturing practices implementation

- On-site consultation

- Supply chain optimization

We serve as a true one-stop-shop for our customers, providing expertise, manufacturing flexibility, and the highest quality products and services. Our unrelenting attention to quality and customer satisfaction has earned us many certifications, including:

- ISO 9001:2015

- Kaizen/5S

- Lean manufacturing

- Six-Sigma (Black Belt)

If the customer requests a quicker than typical turnaround for their project, our experienced staff will do their best to provide it. This includes any rush services that customers may require in emergencies.

To learn more about our electropolishing solutions for stainless steel or other capabilities, contact us today. If you’re looking to partner with a value-added supply chain manufacturer, request a quote with your project requirements.

Contact Us Request For Quote