MIG Welding Guide

Welding encompasses a wide range of techniques that are used to fuse two or more metal parts. Metal Inert Gas welding, or MIG welding, is one of the most common and versatile welding methods, offering clean, reliable welds on a wide range of metals.

At FZE Manufacturing Solutions, we are an industry-leading provider of full-service manufacturing and machining services, including a wide range of welding services for metal components. With our MIG welding capabilities, we can meet the requirements of any aluminum or steel welding project. From contract jobs to production runs for small to medium-sized parts, we have the experience and expertise to meet the needs of various industries, including agriculture, hydraulics, oil & gas, and more.

What Is MIG Welding?

- MIG welding, also known as Gas Metal Arc Welding (GMAW), is one of many welding techniques that utilizes electricity to join metal pieces. During the process, an arc forms between a metal electrode and the workpiece, which melts the electrode to form a weld bead. MIG welding is a quick, simple, and highly beneficial welding technique that is suitable for a wide range of metals and material thicknesses.

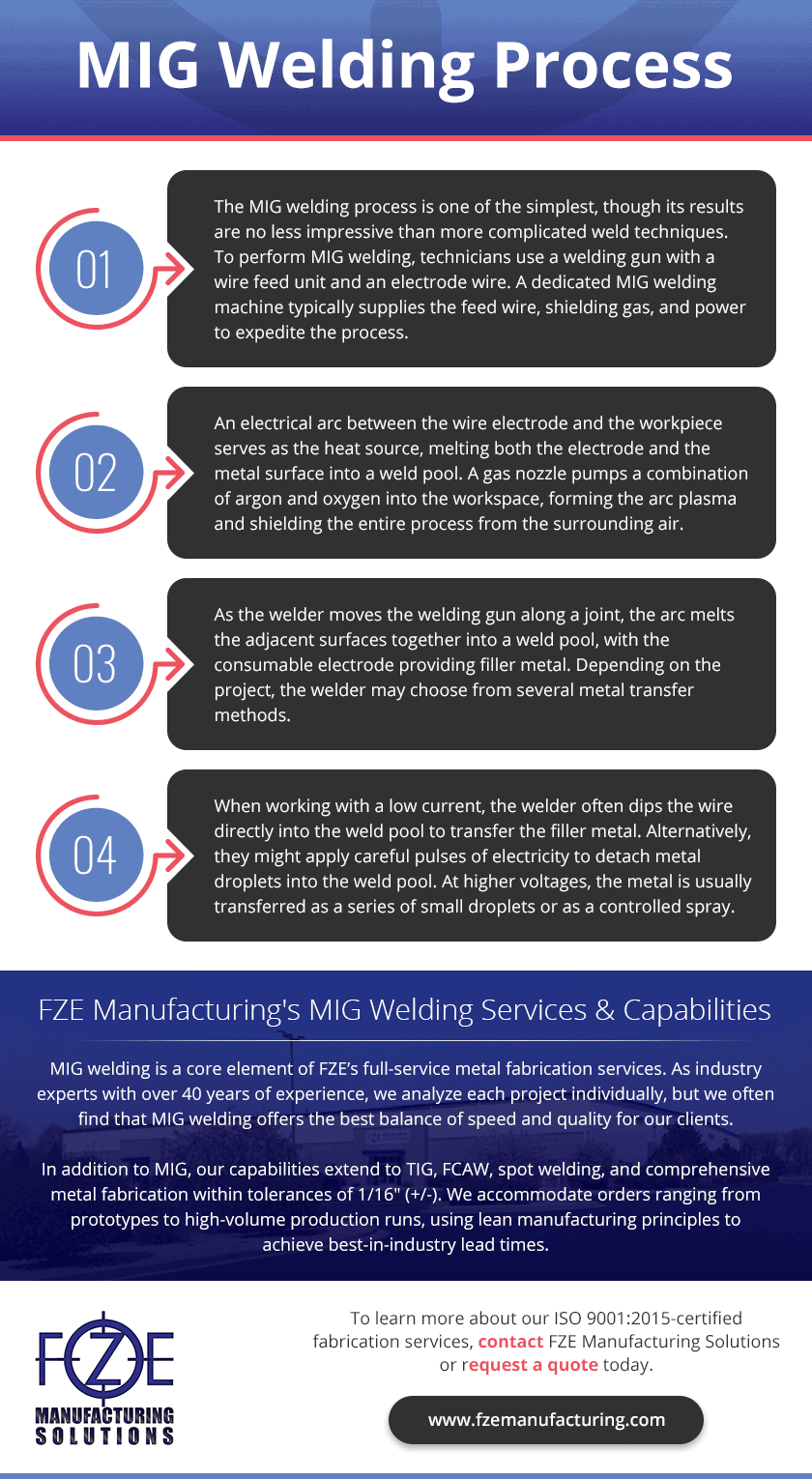

MIG Welding Process

The MIG welding process is one of the simplest, though its results are no less impressive than more complicated weld techniques. To perform MIG welding, technicians use a welding gun with a wire feed unit and an electrode wire. A dedicated MIG welding machine typically supplies the feed wire, shielding gas, and power to expedite the process.

An electrical arc between the wire electrode and the workpiece serves as the heat source, melting both the electrode and the metal surface into a weld pool. A gas nozzle pumps a combination of argon and oxygen into the workspace, forming the arc plasma and shielding the entire process from the surrounding air.

As the welder moves the welding gun along a joint, the arc melts the adjacent surfaces together into a weld pool, with the consumable electrode providing filler metal. Depending on the project, the welder may choose from several metal transfer methods.

When working with a low current, the welder often dips the wire directly into the weld pool to transfer the filler metal. Alternatively, they might apply careful pulses of electricity to detach metal droplets into the weld pool. At higher voltages, the metal is usually transferred as a series of small droplets or as a controlled spray.

Benefits of MIG Welding

MIG welding is compatible with almost any metal, and it is a common choice for mild steel and aluminum fabrication. Other benefits include:

- Efficient. MIG welding is semi-automated, with a machine continuously feeding the electrode wire into the weld pool. Accordingly, MIG welding is one of the most efficient welding methods, allowing welders to join long seams without stopping.

- Clean. MIG welding does not use flux and it creates only minimal splatter. The resulting welds are uniform and slag-free, and welders waste little time cleaning up stray material.

- Minimal Waste. By using continuously-fed wire, MIG welding eliminates the waste inherent to techniques like stick welding, in which the end of the electrode must be discarded. As a result, MIG welding achieves excellent deposition efficiency at a minimal material cost.

- Effective at Many Angles. MIG welding is effective for horizontal, vertical, and overhead welds, so long as the welding gun is held at an appropriate angle.

MIG Welding vs. TIG Welding

Tungsten Inert Gas (TIG) welding is another common welding technique, and it is similar to MIG in many respects. The primary difference is that TIG welding uses a non-consumable tungsten electrode, which may be combined with a consumable filler rod to create a larger weld bead. As in MIG welding, the electrical arc forms between the tip of the electrode and the workpiece, creating a weld pool that is shielded with an inert gas (typically 100% argon, in the case of TIG).

If using filler, the operator pulses the rod into the weld pool to build up the weld bead.

TIG welding is known for creating precise, high-quality welds with an attractive finish. However, being a manual process, TIG is much slower than MIG, even for skilled technicians. TIG welding is also less effective when working with larger or thicker sheet metals. In these cases, MIG is typically the faster and more effective option.

Other Types of Welding

Although MIG and TIG are among the most popular welding techniques, many other methods exist. Your metal fabrication team will guide you toward the most effective option for your project.

- SMAW

Stick Welding / Shielded Metal Arc Welding (SMAW)

Stick welding is the most basic welding technique. In SMAW, the shielding gas comes from flux—a coating on the electrode that releases shielding gas when burned. Unlike MIG, the electrode is not fed continuously; it must instead be replaced periodically. Because of this, SMAW produces more waste and requires more downtime than MIG welding. The use of flux also makes SMAW considerably messier. - FCAW

Flux-Cored Arc Welding (FCAW)

Like MIG, FCAW uses continuous feeding and a consumable electrode. However, FCAW does not require the use of a shielding gas (although one is sometimes incorporated). Instead, FCAW electrodes contain flux on the interior, so melting the electrode releases the necessary shielding gas on its own. Although messier and less precise than MIG, FCAW is sometimes chosen for its portability, especially when welding outdoors. - Energy Beam Welding

Electron Beam Welding (EBW)

Electron Beam Welding (EBW) and Laser Beam Welding (LBW) both use a focused beam of energy to create narrow, precise welds. Both EBW and LBW are fast and effective, yielding clean welds with tiny heat-affected zones. These results come at a high price, though, so energy beam welding is usually only used when necessary for small or intricate components. - AHW

Atomic Hydrogen Welding (AHW)

AHW is a unique process that uses two tungsten electrodes and hydrogen shielding gas. The arc forms between the two electrodes and persists independent of the workpiece. Lowering the arc to the surface creates the weld pool. Although not necessary, filler metal can be used to build up the weld bead. AHW has largely fallen out of favor with the advent of MIG and TIG welding, both of which achieve comparable results using cheaper shielding gas. - PAW

Plasma Arc Welding (PAW)

PAW is very similar to TIG, or Gas Tungsten Arc Welding (GTAW). However, in PAW, the tungsten electrode is isolated in the body of the torch, meaning that the plasma gas is isolated from the shielding gas. Forcing the plasma through the nozzle creates a stiff, constricted arc. At high currents, PAW is similar in effect to the energy beam welding techniques and is similarly well-suited to thick metal. While PAW improves on TIG's penetration, it tends to be more demanding on the welder than TIG. - Spot Welding

Spot Welding

Spot welding is an expedited process used to fuse two pieces of sheet metal together. As a resistance welding method, spot welding does not use an arc or a filler material. Instead, spot welding uses copper electrodes to melt metals together with electrical current. Spot welding is often used when full automation is required.