As a strong material with a protective layer of oxidized chromium, stainless steel loses its corrosion resistance when the protective surface is abraded. Traditional marking and etching processes often use corrosive chemicals and abrasive materials, while inked markings can wear off over time. To avoid these problems, FZE Manufacturing Solutions uses specialized laser technology to create lasting markings on a variety of stainless steel components.

What is Laser Marking?

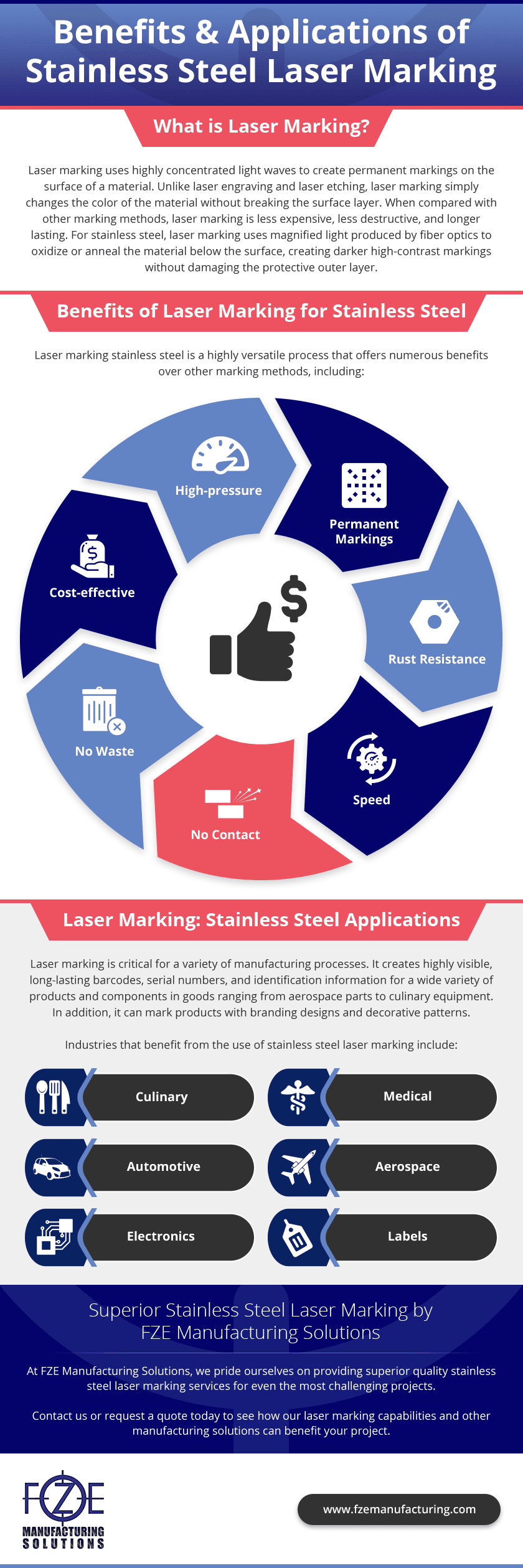

Laser marking uses highly concentrated light waves to create permanent markings on the surface of a material. Unlike laser engraving and laser etching, laser marking simply changes the color of the material without breaking the surface layer. When compared with other marking methods, laser marking is less expensive, less destructive, and longer lasting. For stainless steel, laser marking uses magnified light produced by fiber optics to oxidize or anneal the material below the surface, creating darker high-contrast markings without damaging the protective outer layer.

Benefits of Laser Marking for Stainless Steel

Laser marking stainless steel is a highly versatile process that offers numerous benefits over other marking methods, including:

- Permanent markings. Laser marking creates permanent marks by modifying the chemical composition of the steel under the surface layer. The resultant high-contrast marks are durable and resistant to heat and UV rays, for a highly visible, durable mark that will withstand abrasive cleaning and high temperatures.

- Rust resistance. The surface of stainless steel is highly resistant to rust and must remain intact for the material to maintain its corrosion resistance. By chemically modifying the material beneath the surface, laser marking leaves that layer intact.

- Speed. Laser marking is exceptionally quick, using computerized control, automation, and cutting-edge optics systems to create accurate, repeatable markings with speed and efficiency.

- No contact. Unlike other marking methods, laser marking is a no-contact method, thereby reducing the potential for scratches or stress on the material. This is particularly important for stainless steel, as any scratch or abrasion can compromise the protective surface.

- No waste. Traditional etching and printing methods produce waste material by removing part of the surface layer or employing ink. Since laser marking modifies the structure of the underlying layer of stainless steel, it does not require additive or subtractive processes that can produce waste.

- Cost-effective. Laser marking does not require consumables such as ink and chemicals, and it uses less energy than other marking methods. This makes it a highly cost-effective process.

- High-pressure. Because laser marking does not stress or compromise the surface of components, there’s no risk of creating weaknesses in the part that might fail under exposure to pressure, impacts, and other extreme conditions.

Laser Marking: Stainless Steel Applications

Laser marking is critical for a variety of manufacturing processes. It creates highly visible, long-lasting barcodes, serial numbers, and identification information for a wide variety of products and components in goods ranging from aerospace parts to culinary equipment. In addition, it can mark products with branding designs and decorative patterns.

Industries that benefit from the use of stainless steel laser marking include:

- Culinary. Laser marking creates product labels, branding, and component identification for stainless steel knives, cookware, and appliances.

- Medical. The medical industry uses laser-marked stainless steel for device components, as well as surgical tools and diagnostic and clinical equipment.

- Automotive. Laser marked stainless steel automotive components offer superior traceability, including steering and suspension systems, brakes, engines, and exhaust components.

- Aerospace. Stainless steel components used in airplane engines, panels, fixtures, landing gear, and other components must be clearly marked and traceable.

- Electronics. Electronics such as computers, cell phones, and tablets require small, easily identified stainless steel components for PCBs, circuits, and other critical operations.

- Labels. Laser-marked stainless steel is critical for labeling heavy-duty and high-performance components in a variety of industrial, commercial, and other harsh settings.

Superior Stainless Steel Laser Marking by FZE Manufacturing Solutions

At FZE Manufacturing Solutions, we pride ourselves on providing superior quality stainless steel laser marking services for even the most challenging projects. Contact us or request a quote today to see how our laser marking capabilities and other manufacturing solutions can benefit your project.