Laser marking allows manufacturers to mark pieces or components with high-precision semi-permanent or permanent markings. Unlike laser engraving or laser etching, laser marking is non-subtractive and does no damage to the actual material. This makes it very versatile in an array of industries and applications, letting companies add serial numbers, part numbers, and other details to various metals, including aluminum.

FZE Manufacturing has been providing aluminum laser marking and other manufacturing solutions for nearly half a century. We can work with you and your specific application needs regardless of your industry.

What Is Laser Marking?

Laser marking uses a concentrated beam of light to add a very precise mark to your component’s material. The process results in a high-contrast color change in your material, which doesn’t alter or remove any of the underlying material the way that etching or engraving does. This makes laser marking the go-to solution for manufacturers who need very precise, very accurate markings that don’t affect the underlying structure, strength, or integrity of an aluminum component.

Laser marking is commonly used in industries such as automotive, aerospace, electronics, and medical device manufacturing to label products with key tracking info or details (e.g., traceability lots, part numbers, production dates, etc.). The extreme precision of laser marking allows marks to be scanned, making it popular when etching QR codes, barcodes, and similar labels.

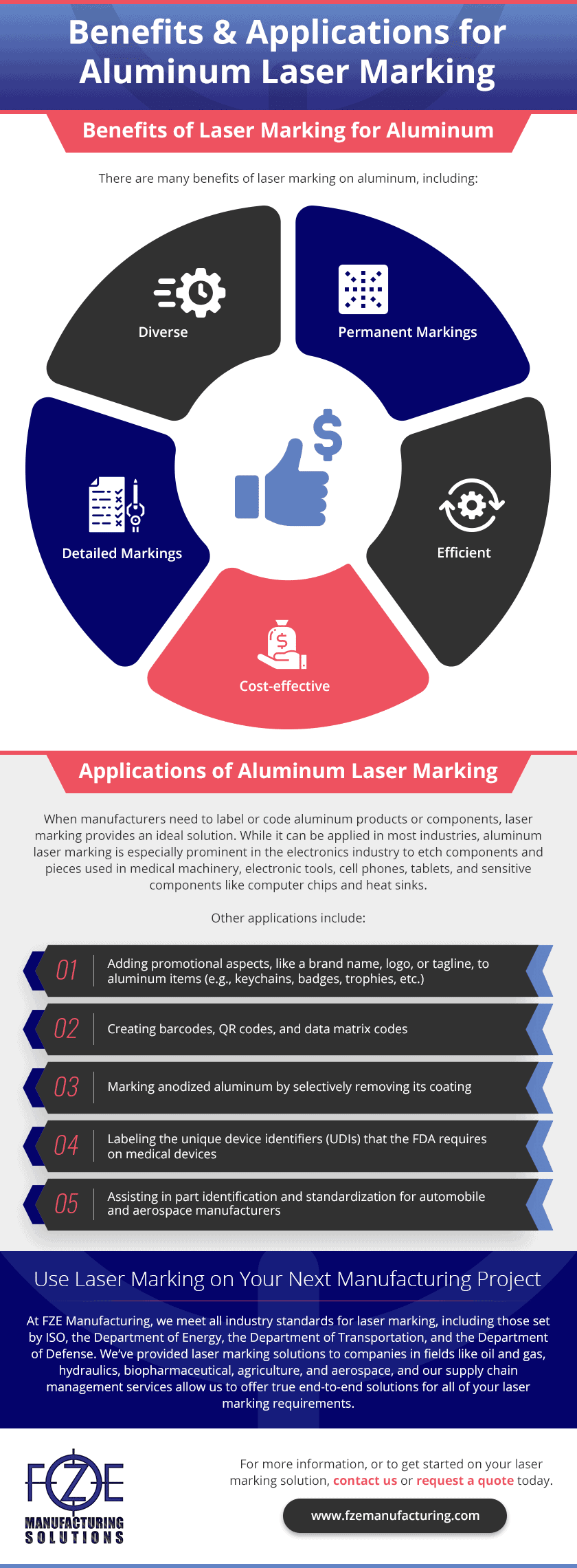

Benefits of Laser Marking for Aluminum

There are many benefits of laser marking on aluminum, including:

- Permanent markings. Compared to other marking methods, laser marking results in a permanent marking that is resistant to elements such as heat, abrasion, and acid.

- Efficient. Laser marking can rapidly create a variety of markings, such as serial numbers or other codes, without the need for tool changes or refitting. Laser machines are also very low maintenance, further boosting productivity.

- Cost-effective. Since laser marking is a direct marking process, it doesn’t require additional materials such as inks or sprays. It also doesn’t require pre- or post-treatment.

- Detailed markings. Laser marking can accurately achieve detailed and intricate markings even with the smallest geometries.

- Diverse. Laser marking can create a wide range of markings, including barcodes, logos, serial numbers, designs, and more.

Applications of Aluminum Laser Marking

When manufacturers need to label or code aluminum products or components, laser marking provides an ideal solution. While it can be applied in most industries, aluminum laser marking is especially prominent in the electronics industry to etch components and pieces used in medical machinery, electronic tools, cell phones, tablets, and sensitive components like computer chips and heat sinks.

Other applications include:

- Adding promotional aspects, like a brand name, logo, or tagline, to aluminum items (e.g., keychains, badges, trophies, etc.)

- Creating barcodes, QR codes, and data matrix codes

- Marking anodized aluminum by selectively removing its coating

- Labeling the unique device identifiers (UDIs) that the FDA requires on medical devices

- Assisting in part identification and standardization for automobile and aerospace manufacturers

Use Laser Marking on Your Next Manufacturing Project

When you need highly accurate marks added to your aluminum products or components, FZE Manufacturing’s laser marking services can provide the ideal solution. Our laser marking machinery can quickly and efficiently create precise and high-quality markings for a variety of industries and applications.

At FZE Manufacturing, we meet all industry standards for laser marking, including those set by ISO, the Department of Energy, the Department of Transportation, and the Department of Defense. We’ve provided laser marking solutions to companies in fields like oil and gas, hydraulics, biopharmaceutical, agriculture, and aerospace, and our supply chain management services allow us to offer true end-to-end solutions for all of your laser marking requirements.

For more information, or to get started on your laser marking solution, contact us or request a quote today.