What is shaft manufacturing? A shaft or a gear is a toothed wheel that meshes with another shaft’s teeth to continually transmit rotational power. Engineers can mix and match shafts and gears of different diameters to vary the force and speed of these components’ rotation.

Shafts have several important uses in the aerospace, agriculture, automotive, consumer products, transportation, oil & gas, mining, and industrial manufacturing fields. These tools generate and channel torque force in a wide range of mechanical equipment, from cars and planes to machines and appliances to do work.

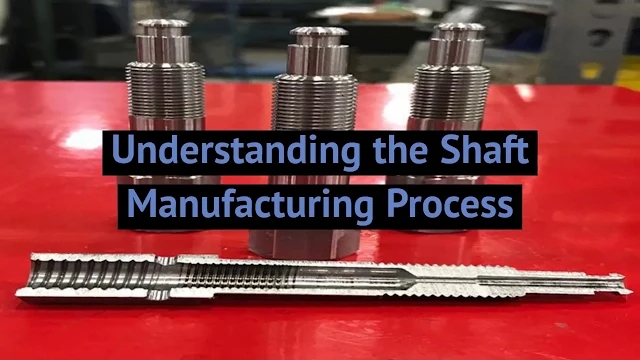

In this post, we explore a few aspects of the shaft manufacturing process, as well as how we use innovative techniques to manufacture shafts for the industries we serve.

How the Shaft Manufacturing Process Works

What is shaft manufacturing and how does it work? The most common process used to manufacture shafts is via CNC turning and machining. Using this technique, workers or automated processes affix or chuck bars of materials in chucks or collets and rotate them. While rotating, specialized tools use cutting and other subtractive processes to shape the end geometry and final product.

FZE uses many different machining processes to create its shafts. Our facility houses a wide range of state-of-the-art equipment designed to optimize even the most complex aspects of the shaft-manufacturing processes. From custom tooling and fixturing to multi-axis equipment, we use all types of machinery to produce extremely precise shafts to tolerances within 0.0002” (0.00508 mm).

FZE’s Shaft-Manufacturing Capabilities

FZE works with over three dozen types of raw materials to produce high-quality shafts that adhere to client specifications. We build shafts using materials ranging from:

- Ferrous metals: standard alloy & carbon steels, stainless steels, Inconel and titanium

- Non-Ferrous metals: aluminum, brass, bronze and other exotic or precious metals

- Plastics and other polymers

- Graphite and other non-metal materials

We also work with a vast array of part sizes, with our capabilities listed here as they apply to the following dimensions:

- Diameter: We build parts as small as 0.10” diameter and as large as 25” diameter

- Length: Our parts range from 1” to 60” in length

- Face grooves: We build shafts with face grooves depths of varying geometry

- Weight: Our typical shafts have a maximum weight of up to 1,000 lbs.

Machining Processes

We bring many types of machining processes to bear when it comes to shaft manufacturing. A sample of our production capabilities includes:

- Boring

- Drilling

- Turning

- Internal and external threading

- Internal and external spinning and teeth cutting

- Rotary Broaching

- And more

We also perform a diverse array of secondary services to fine tune the product to your specifications. Some secondary service options we provide include:

- Anodizing

- Plastic mold insertion

- Bushing Assembly

- Bending

- Broaching

- Heat treating

- Passivating

- Electro-Polishing

- Welding

Quality Shafts and Finishing Operations from FZE Manufacturing

FZE uses special shaft manufacturing techniques to maximize our efficiency without sacrificing product quality or your bottom line. Our experience in this field allows us unparalleled customization capabilities, which enables us to properly produce shafts for each client as needed. What is shaft manufacturing? It’s a process that we have mastered to help you create shafts to your exact specifications.

For more information on how we can help you create shafts to your exact specifications, please don’t hesitate to contact us today.