Fiber lasers have been around since 1998 and they became more popular in 2011, when new nanosecond units with a wide range of applications, were introduced to the market. Fiber lasers share the market with Gas lasers that are more common. However, fiber laser marking machines are becoming increasingly popular because of their many benefits.

What Is Fiber Laser Marking?

Fiber laser marking refers to the process of leaving an impression on items using a fiber laser beam of light. The marking machine extracts concentrated energy from light and uses it as the laser beam. The light is passed through an f-theta lens, which is designed to maintain its focus on the whole plain as opposed to just one spot. The concentrated laser beam leaves distinct marks when passed over a material’s surface.

Different materials absorb light wavelengths at different rates, so varying types of fiber laser machines provide varying light wavelengths.

Benefits of Fiber Laser Marking

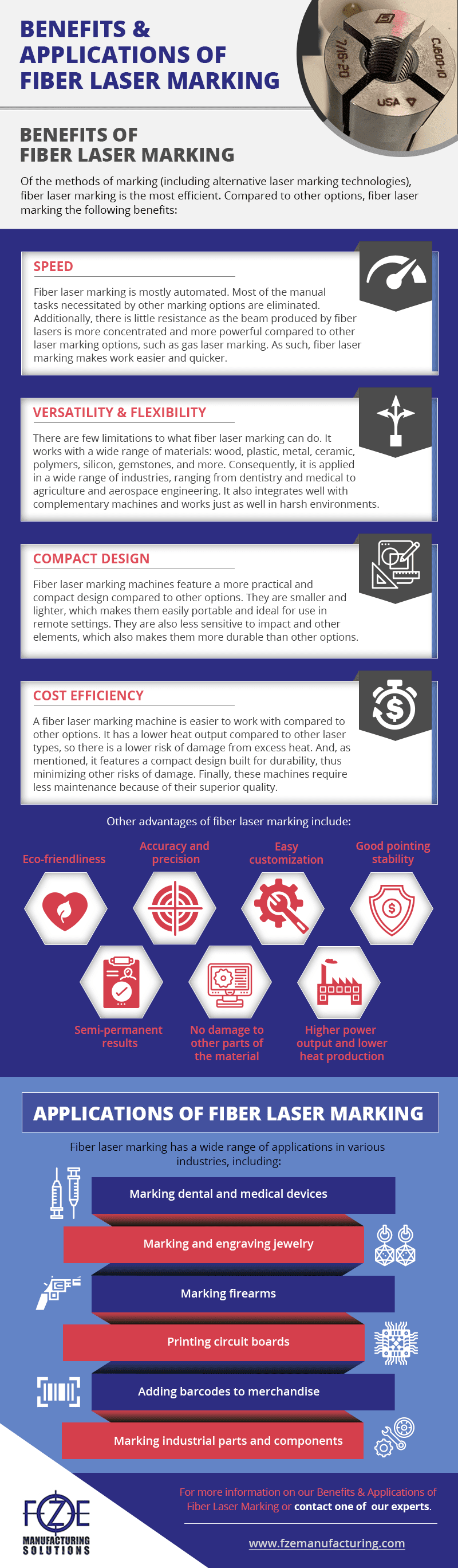

Of the methods of marking (including alternative laser marking technologies), fiber laser marking is the most efficient. Compared to other options, fiber laser marking has the following benefits:

SPEED

Fiber laser marking is mostly automated. Most of the manual tasks necessitated by other marking options are eliminated. Additionally, there is little resistance as the beam produced by fiber lasers is more concentrated and more powerful compared to other laser marking options, such as gas laser marking. As such, fiber laser marking makes work easier and quicker.

Versatility & Flexibility

There are few limitations to what fiber laser marking can do. It works with a wide range of materials: , plastic, metal, ceramic, polymers, silicon, gemstones, and more. Consequently, it is applied in a wide range of industries, ranging from dentistry and medical to agriculture and aerospace engineering. It also integrates well with complimentary machines and works just as well in harsh environments.

Compact Design

Fiber laser marking machines feature a more practical and compact design compared to other options. They are smaller and lighter, which makes them easily portable and ideal for use in remote settings. They are also less sensitive to impact and other elements, which also makes them more durable than other options.

Cost Efficiency

A fiber laser marking machine is easier to work with compared to other options. It has a lower heat output compared to other laser types, so there is a lower risk of damage from excess heat. And, as mentioned, it features a compact design built for durability, thus minimizing other risks of damage. Finally, these machines require less maintenance because of their superior quality.

Other advantages of fiber laser marking include:

- Eco-friendliness

- Accuracy and precision

- Easy customization

- Good pointing stability

- Semi-permanent results

- No damage to other parts of the material

- Higher power output and lower heat production

The benefits of fiber laser marking are not limited to these listed above. Advances in the design and technology are giving rise to even more significant benefits.

Applications of Fiber Laser Marking

Fiber laser marking has a wide range of applications in various industries, including:

- Marking dental and medical devices

- Marking and engraving jewelry

- Marking firearms

- Printing circuit boards

- Adding barcodes to merchandise

- Marking industrial parts and components

Industries that rely on fiber laser marking applications include:

- Dental, Medicine and health care

- Electronics manufacturing

- Aerospace manufacturing

- Additive manufacturing

- Automotive and Aerospace industries

- Integrated electronics and circuit industries

Laser Marking Services by FZE Manufacturing Solutions

FZE makes superior quality fiber laser marked products for a wide range of applications. Our machines are effective with a variety of materials, including:

- All Industrial Metals

-

- All Aluminum

- All Brass & Bronze

- All Copper

- All Iron

- All Steel

- All Stainless Steel

- Any Heat Resistant Metals (Titanium, Hastalloy, Inconnel, etc.)

- Light and perforated metals

- Plastics

- Leather

- Ceramic

Would you like to learn more about FZE’s fiber laser marking capabilities and what they can do for you? Get in touch today.