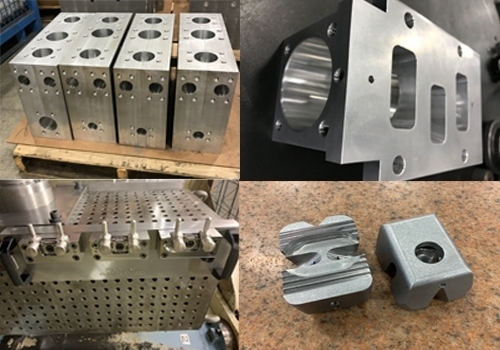

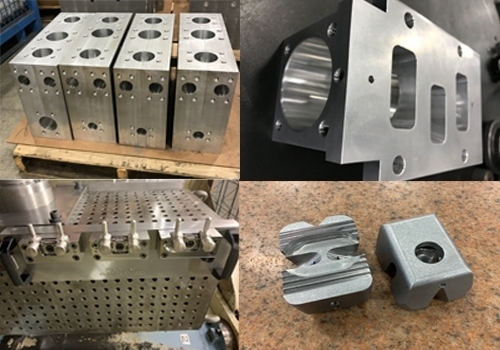

CNC, HMC & VMC Machining Services

Our machining services utilize the latest in robotic automation and 3-axis, 4-axis, and 5-axis CNCs to deliver precision components and assemblies from various metals, plastics, and composites. Our machinists are highly skilled in projects, including prototype parts, low-volume runs, and large production orders.

Using advanced CNC machining service technology, we provide services from simple to complex machining. CNC stands for Computer Numerical Control, a programmable machine that uses pre-programmed computer software to control the motion and position of machine tools.

CNC machines cut exact shapes from metals and materials like plastic. VMC machining builds upon CNC technology by providing more movement on the workpiece, with additional axes allowing for cylindrical surfaces and contours that cannot be achieved with CNC machining alone.

With our array of CNC, HMC & VMC machining services, we can precisely customize components according to customer specifications.

Learn More

CNC Swiss Machining Services

Precision Swiss machining services are invaluable to any high-precision metal parts manufacturing process. This type of CNC machining uses specially designed turning machines equipped with CNC technology and up to 8-axis capabilities to create intricate parts and components from many different raw materials, including:

- Stainless Steels

- Carbon and Alloy Steels

- Aluminum

- Brass & Bronze

- Plastic compounds

Swiss machining services provide shorter lead times and greater accuracy than other CNC machining techniques, allowing operators to process complex shapes with bar feed equipment in one setup and complete multi-axis jobs quickly and efficiently.

With FZE’s Swiss machining services, you can remain confident that all production parts delivered meet your quality expectations for higher tolerance requirements.

Learn More

Shaft Machining

Shaft machining is a process offered by FZE that provides customers with precision machining of shafts and other related parts. It allows for accuracy, repeatability, and quality assurance standards that meet industry expectations.

Shaft manufacturing is used to cut, shape, or turn and mill materials efficiently and cost-effectively; it can be used for single-piece work through large-volume production runs.

Advanced technology and the latest machining techniques are available to ensure products are completed quickly while providing consistent quality – ensuring they will meet each customer’s specific needs.

Learn More

Hydraulic Components Machining

Hydraulic components machining is a comprehensive machining solution offered by FZE. Hydraulic machining creates or modifies hydraulic components such as valves and cylinders, ensuring proper functionality.

This specific service includes a variety of techniques, ranging from manual labor to computer-aided design and machining. Hydraulic component machining utilizes advanced technology and engineering principles to offer precise tolerances and cuts to metals, plastics, polymers, and ceramics, making it an ideal solution for many industries.

Learn More

Welding Services

Our welding services specialize in combining multiple metals and components with expert attention to detail, ensuring the longevity of our manufacturing work. Our welding techniques use a variety of safety standards and procedures, including gas metal arc welding (GMAW) (MIG), flux-cored arc welding (FCAW), and tungsten inert gas (TIG) welding.

In addition to our standard welding services, our team can develop custom solutions to meet individual needs such as robotic welding services for medium to high quantity orders.

Learn More

Fabrication Services

FZE offers fabrication services that provide customers custom solutions tailored to fit their needs. This includes designing, forming, and assembling components for industrial equipment.

Fabrication services utilize state-of-the-art technology to ensure efficiency, quality fabrication, and excellent customer service from start to finish.

Learn More

Part Assembly

Part assembly and Kitting are essential capabilities provided by FZE. This vital service involves inspecting each part to ensure it meets specifications and assembling those parts into complete products for improved performance and reliability.

Part assembly is an invaluable process that can result in cost savings, reduced waste, and improved product quality throughout the life cycle of a project.

Kitting is grouping assembled parts together into a “kit” to provide a ready for assembly line offering.

Learn More

Machining Inspection & Quality Assurance

Machining inspection & quality assurance from FZE offers comprehensive and reliable quality assurance services for machined parts. With extensive PPAP and APQP experience in pre-production to post-production First Articles and ISIR inspection services, the machining inspection & quality assurance team is equipped to deliver the highest quality assurance standards in accordance with their ISO 9001:2015 Certification.

Services include visual inspections, dimensional checks, material certification, in-process inspections, and document verification. Working with the latest metrology gages, tools, and CMM equipment, they provide clear reporting that helps customers comply with industry standards while ensuring that their manufactured parts meet the required precision requirements.

Learn More

Laser Marking Services

Laser marking services offered by FZE is a great way to customize and process parts for industrial products. Laser marking services are a perfect way to accurately, quickly and permanently label components with custom data such as serial numbers, promotional designs, unique logos, identification codes, etc.

Laser marking services use laser beams of light that work on metal and non-metal materials. Laser marking services reduce errors while ensuring that templating is done correctly with high precision and quality.

Learn More

Stainless Steel Passivation Services

Stainless steel passivation services from FZE is an advanced process to remove surface contaminants from stainless steel components. This process restores the passive layer in the metal, which is a protective barrier against corrosion and oxidation.

Stainless steel passivation services enhance the lifespan of the material and its performance in harsh conditions. It also improves product appearance, provides a smoother finish, reduces corrosion, and helps prevent contamination of nearby materials.

Learn More

Stainless Steel Electropolishing Services

Stainless steel electropolishing services offered by FZE is the ideal solution for boosting the corrosion resistance performance and appearance of stainless steel. This process creates a uniform, textured polished surface on stainless steel and other metals to obtain characteristics such as:

- Increased corrosion resistance

- Improved fatigue strength

- Visual aesthetics

- Hygienic advantages

Stainless steel electropolishing services also help enhance product lifespan by eliminating imperfections that can cause microscopic cracks like welding lines and preserving fine details to keep stainless steel components looking beautiful and performing their best.

Learn More

Industries Served

FZE Manufacturing Solutions provides precision-machined components and assemblies for a variety of industries, ensuring high performance, reliability, and compliance with industry standards. Our expertise spans multiple sectors, delivering specialized parts for demanding applications.

- Aerospace – Precision-machined components for aircraft structures, engine parts, and landing gear systems.

- Automotive – Custom shafts, hydraulic fittings, and specialized fasteners for vehicle manufacturing.

- Agriculture – Durable machined parts for tractors, harvesters, and irrigation systems.

- Hydraulics – Cylinders, rods, and valves for fluid power applications in heavy machinery.

- Medical – High-precision components for surgical instruments and medical device assemblies.

- Marine – Corrosion-resistant shafts, fittings, and propulsion system components.

- Industrial Equipment – Custom-machined parts for manufacturing, automation, and heavy-duty applications.

Manufacturing and machining experts

FZE is a provider of comprehensive manufacturing and machining services with extensive capabilities. We assist you in streamlining your operations, reducing expenses, and enhancing quality. Our services include engineering assistance, prototyping, and manufacturing, machining, finishing, assembly, and packaging.

Contact us today if you are seeking a partner to assist you with your production needs. We are delighted to discuss how we can help you increase productivity and enhance your bottom line.