TIG Welding Services

TIG welding is the preferred fabrication method in a variety of applications. It offers exceptional versatility and leaves a clean weld on various materials. At FZE Manufacturing, we provide high-quality manufacturing and fabrication services like TIG welding. We use a variety of materials and the leading technology to provide clean and precise fabrication.

When determining if TIG welding is the ideal fabrication service for your application, an overview of TIG welding is helpful. We will explore the industries and applications that depend on TIG welding, along with the benefits of this welding technique.

What Is TIG Welding?

Tungsten Inert Gas, or TIG welding, is one of many welding techniques used to form a permanent bond between metal parts. This welding method uses a non-consumable tungsten electrode to create an electrical arc that heats the material of the workpieces so that they melt and join together. The tip of the electrode is enveloped in an inert shielded gas barrier, such as helium or argon, to prevent contamination of the weld pool or puddle.

Typically, TIG welding requires a filler rod, but it can join almost any metal. This welding method delivers many advantages over other fabrication methods, making it ideal for many industries and applications.

Get In Touch Today

Fill out the form below to start a conversation

Advantages of TIG Welding

Choosing TIG welding over other fabrication methods provides various advantages. The arc created by the tungsten electrode is small and has a high level of precision. Its intense heat delivers high-quality welds for a wide range of substrates in combination with a filler rod. The welds are clean and require no preparation or post-weld cleanup. TIG welding does not require flux and will not create slag, smoke, or sparks.

TIG welding offers high versatility to the welder. It can be used in various locations while providing maximum control to the welder. TIG welding can accommodate numerous welding positions, making it perfect for awkward angles and small spaces. The permanent bond created by TIG welding is high-strength and has an innate resistance to corrosion.

TIG Welding Industries and Applications

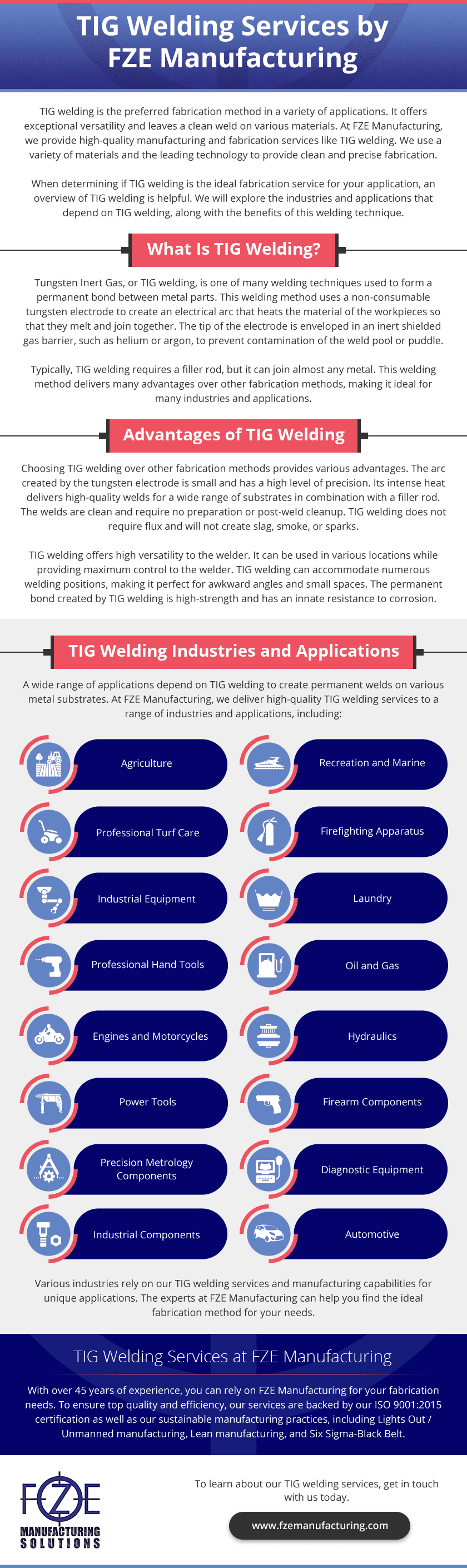

A wide range of applications depend on TIG welding to create permanent welds on various metal substrates. At FZE Manufacturing, we deliver high-quality TIG welding services to a range of industries and applications, including:

- Agriculture

- Recreation and Marine

- Professional Turf Care

- Firefighting Apparatus

- Industrial Equipment

- Laundry

- Professional Hand Tools

- Oil and Gas

- Engines and Motorcycles

- Hydraulics

- Power Tools

- Firearm Components

- Precision Metrology Components

- Diagnostic Equipment

- Industrial Components

- Automotive

Various industries rely on our TIG welding services and manufacturing capabilities for unique applications. The experts at FZE Manufacturing can help you find the ideal fabrication method for your needs.

TIG Welding Services at FZE Manufacturing

TIG welding is an ideal fabrication technique for its clean and precise welds. It can bond a variety of metals and provides versatility and control for many applications. At FZE Manufacturing, we use TIG welding to fabricate metals for various applications and industries. Our welding capabilities include working with materials with thicknesses ranging from 0.3 to 3 inches and weights up to 2,000 lbs. Our facilities can accommodate pieces up to 120 feet in width or length and 36 feet in height. We can meet tight tolerances within 1/16 (+/-) of an inch and offer FCA, MIG, and spot welding along with expert machine inspection.

With over 45 years of experience, you can rely on FZE Manufacturing for your fabrication needs. To ensure top quality and efficiency, our services are backed by our ISO 9001:2015 certification as well as our sustainable manufacturing practices, including Lights Out / Unmanned manufacturing, Lean manufacturing, and Six Sigma-Black Belt.