MIG Welding Services

FZE Manufacturing is a premier metal fabricator, providing full-service machining and manufacturing services in support of an expansive range of industries. Our welders have extensive expertise in numerous metal welding processes for mild carbon steel, stainless-steel or aluminum welding projects, including metal inert gas (MIG) welding.

What is MIG Welding?

A form of arc welding, MIG welding is the most common welding technique. This highly versatile form of welding is also called gas metal arc welding (GMAW). MIG welding creates an electrical arc between a consumable metal electrode on the welding gun and the metal surface of the workpiece. As this electrode melts, it creates a weld pool that helps to create a firm joint between the two items being welded together. An inert shielding gas prevents the melted metal from reacting to atmospheric contaminants or elements.

Get In Touch Today

Fill out the form below to start a conversation

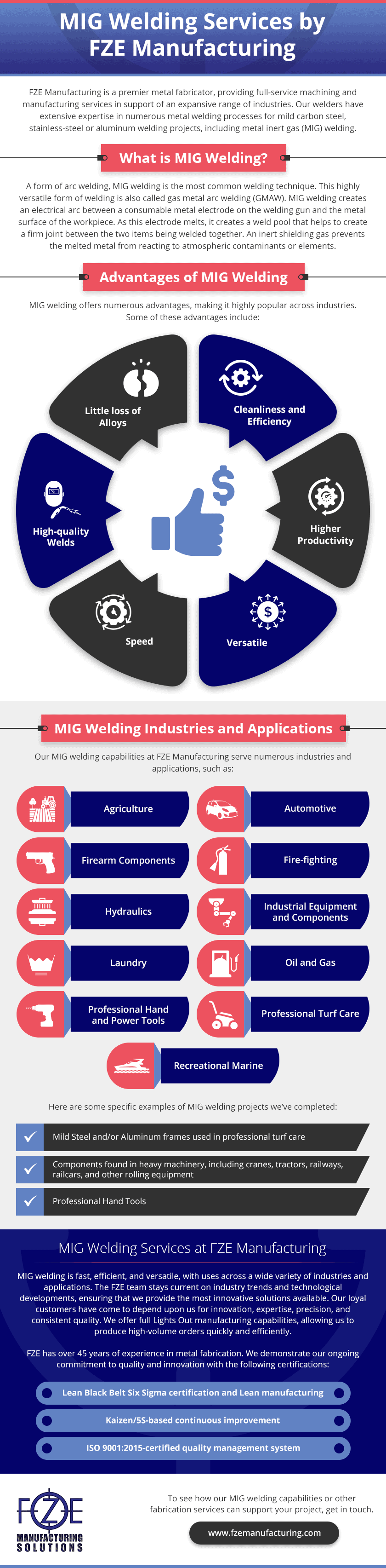

Advantages of MIG Welding

MIG welding offers numerous advantages, making it highly popular across industries. Some of these advantages include:

- Cleanliness and efficiency. MIG welding is often described as a “point-and-shoot” process because it is easy to learn. The process produces clean welds without causing slag buildup or requiring brushing.

- Higher productivity. Given the relatively fast pace of MIG welding compared to other methods and the clean welds it provides facilitates a higher throughput.

- Versatile. MIG welding offers compatibility with a wide variety of metals and alloys, such as stainless steel, aluminum, mild steel, copper, magnesium, nickel, and many other types of alloys, including iron alloys.

- Speed. Since MIG welding uses a continuously fed wire, the welder doesn’t need to stop and start to replace rods or feed the wire. This results in better speed, quality, and control.

- High-quality welds. Since MIG welding is flux-free, it eliminates the risk of trapped slag. That translates to higher quality welds.

- Little loss of alloys. Because MIG welding uses a gas blanket, it minimizes alloy loss compared to many other welding techniques.

MIG Welding Industries and Applications

Our MIG welding capabilities at FZE Manufacturing serve numerous industries and applications, such as:

- Agriculture

- Automotive

- Firearm components

- Fire-fighting

- Hydraulics

- Industrial equipment and components

- Laundry

- Oil and gas

- Professional hand and power tools

- Professional turf care

- Recreational Marine

Here are some specific examples of MIG welding projects we’ve completed:

- Mild Steel and/or Aluminum frames used in professional turf care

- Components found in heavy machinery, including cranes, tractors, railways, railcars, and other rolling equipment

- Professional Hand Tools

MIG Welding Services at FZE Manufacturing

MIG welding is fast, efficient, and versatile, with uses across a wide variety of industries and applications. The FZE team stays current on industry trends and technological developments, ensuring that we provide the most innovative solutions available. Our loyal customers have come to depend upon us for innovation, expertise, precision, and consistent quality. We offer full Lights Out manufacturing capabilities, allowing us to produce high-volume orders quickly and efficiently.

FZE has over 45 years of experience in metal fabrication. We demonstrate our ongoing commitment to quality and innovation with the following certifications:

- Lean Black Belt Six Sigma certification and Lean manufacturing

- Kaizen/5S-based continuous improvement

- ISO 9001:2015-certified quality management system

To see how our MIG welding capabilities or other fabrication services can support your project, get in touch.

Contact Us Request For Quote