High-Precision Laser Marking Services

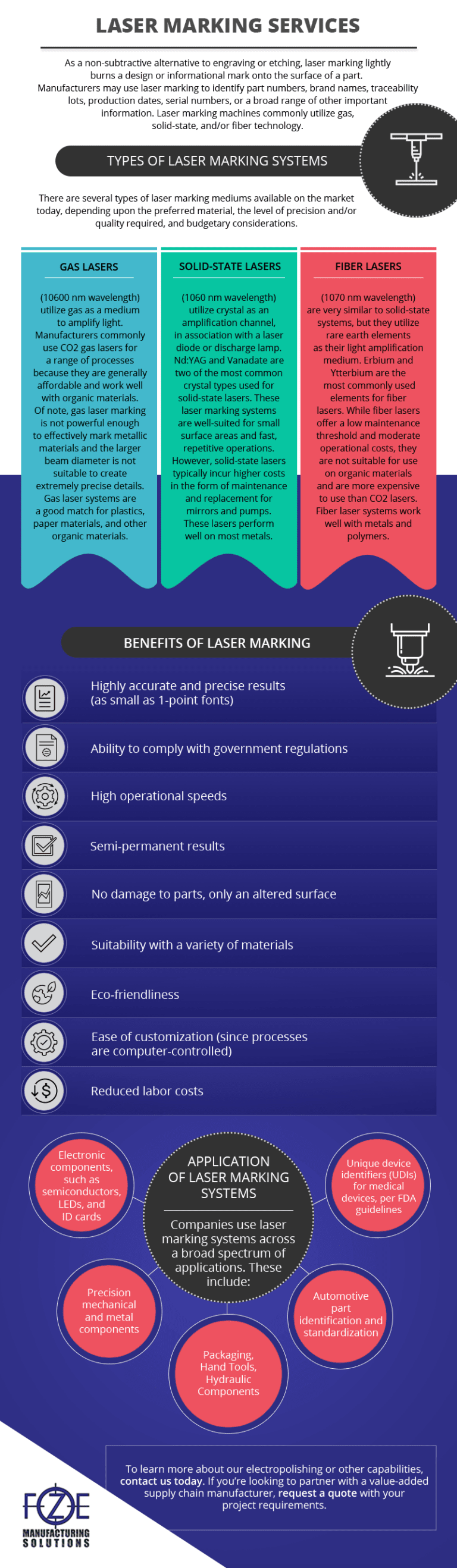

As a non-subtractive alternative to engraving or etching, laser marking lightly burns a design or informational mark onto the surface of a part. Manufacturers may use laser marking to identify part numbers, brand names, traceability lots, production dates, serial numbers, or a broad range of other important information. Laser marking machines commonly utilize gas, solid-state, and/or fiber technology.

There are multiple benefits that come from using laser marking systems, including:

- High precision results

- Fine-detailed markings

- Semi-permanent and permanent options

- No damage inflicted on the target material (non-subtractive)

- Versatility of use across a range of materials, such as metals, plastics, and organics

FZE Manufacturing Solutions has accrued four decades of experience as a full-service manufacturer. We are able to meet stringent laser marking standards such as:

- ISO

- Mil-Spec/Department of Defense (DOD)

- Department of Transportation (DOT)

- Department of Energy (DOE)

Our supply chain management services ensure that our customers receive a true end-to-end solution on laser marking and other manufacturing projects, helping them to reduce costs and maximize efficiency on every project.

Get In Touch Today

Fill out the form below to start a conversation

Types of Laser Marking Systems

There are several types of laser marking mediums available on the market today, depending upon the preferred material, the level of precision and/or quality required, and budgetary considerations.

- Gas lasers (10600 nm wavelength) utilize gas as a medium to amplify light. Manufacturers commonly use CO2 gas lasers for a range of processes because they are generally affordable and work well with organic materials. Of note, gas laser marking is not powerful enough to effectively mark metallic materials and the larger beam diameter is not suitable to create extremely precise details. Gas laser systems are a good match for plastics, paper materials, and other organic materials.

- Solid-state lasers (1060 nm wavelength) utilize crystal as an amplification channel, in association with a laser diode or discharge lamp. Nd:YAG and Vanadate are two of the most common crystal types used for solid-state lasers. These laser marking systems are well-suited for small surface areas and fast, repetitive operations. However, solid-state lasers typically incur higher costs in the form of maintenance and replacement for mirrors and pumps. These lasers perform well on most metals.

- Fiber lasers (1070 nm wavelength) are very similar to solid-state systems, but they utilize rare earth elements as their light amplification medium. Erbium and Ytterbium are the most commonly used elements for fiber lasers. While fiber lasers offer a low maintenance threshold and moderate operational costs, they are not suitable for use on organic materials and are more expensive to use than CO2 lasers. Fiber laser systems work well with metals and polymers.

Benefits of Laser Marking Systems

There are a range of advantages provided by laser marking systems, including:

- Highly accurate and precise results (as small as 1-point fonts)

- Ability to comply with government regulations

- High operational speeds

- Semi-permanent results

- No damage to parts, only an altered surface

- Suitability with a variety of materials

- Eco-friendliness

- Ease of customization (since processes are computer-controlled)

- Reduced labor costs

Application of Laser Marking Systems

Companies use laser marking systems across a broad spectrum of applications. These include:

- Unique device identifiers (UDIs) for medical devices, per FDA guidelines

- Automotive part identification and standardization

- Packaging, Hand Tools, Hydraulic Components

- Precision mechanical and metal components

- Electronic components, such as semiconductors, LEDs, and ID cards

Laser Marking Services and FZE Manufacturing

At FZE Manufacturing, we offer a full portfolio of laser marking services for our clients. We work with several different materials, such as:

- A range of Aluminum alloys

- Brass, Bronze, Copper

- Heat-resistant metals

- All Steels

- Stainless Steels

- Light metal, Perforated metal

Apart from laser marking, we provide several other services, such as:

- Assembly and Kitting

- Electropolishing

- Passivation

- Embossing

- Finishing

- Painting

- Abrasive Polishing

We have the capabilities and expertise to provide our customers with small prototype runs and high-volume production orders alike.

Why Choose FZE Manufacturing for Your Laser Marking Services

FZE Manufacturing Solutions has been operational in the manufacturing industry since 1974. During our four and a half decades of existence, we have delivered high quality work to clients in a range of industries, including:

- Aerospace

- Agriculture and Dairy

- Biomedical/Biopharmaceutical

- DOT/DOD/DOE

- Firefighting and Safety Equipment

- Hydraulics

- Recreational Marine

- Automotive, Motorcycles, Trucking

- Oil and gas

- Professional Turf and Lawn Care

Our team of experts is Six-Sigma certified (Black Belt), and we follow Lean manufacturing principles and Kaizen/5S methodology. We are also ISO 9001:2015 certified.

We offer additional services apart from our core manufacturing solutions, which include:

- Supply chain optimization, such as Just-in-Time (JIT) manufacturing, to reduce costs and shorten lead times

- Onsite consultation, inspection, and quality assurance services

- Rush services and quick turnarounds

If you’d like more information on FZE’s laser marking capabilities or other services, please contact us today.

Contact Us Request For Quote