Hydraulic Components Machining Solutions

For more than four decades, FZE Manufacturing Solutions, LLC, has specialized in machining and manufacturing a wide range of hydraulic parts and components. Our state-of-the-art Swiss, HMC, VMC, and CNC machining capabilities allow us to provide hydraulic machining services for many industries.

Our qualified engineering team and skilled CNC machinists use advanced machining equipment to produce complex fluid control hydraulic parts at high levels of quality and precision.

We manufacture a variety of individual hydraulic components and parts such as cylinder & rods, components for motors, pumps, fittings and hose hardware. Our range of secondary services, including anodizing, heat treating, passivating, plating, and assembly, gives us the ability to provide single-source solutions that simplify our customer’s supply chain, thus reducing manufacturing costs and improving turnaround times and overall customer satisfaction.

Get In Touch Today

Fill out the form below to start a conversation about your hydraulic component machining needs.

What is Hydraulic Component Machining?

Manufacturers use hydraulic components and parts to build custom assemblies for fluid control hydraulic equipment. Due to the ever-present risks of corrosion, fatigue, and excessive wear; machining techniques, materials, and overall product quality must meet or exceed and satisfy hydraulic industry standards and specifications.

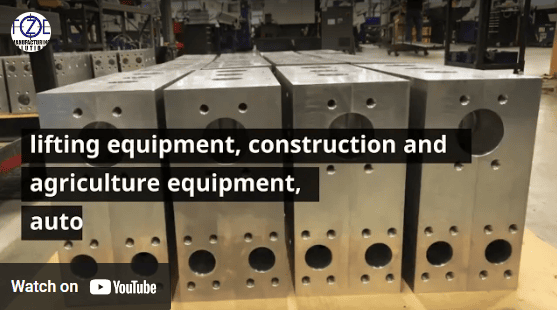

Hydraulic equipment powers a wide range of devices across industries and applications including:

- Lifting equipment (cranes, hydraulic jacks, wheelchair & scissor lifts, etc.)

- Construction & Agriculture equipment

- Automotive and Trucking equipment

- Marine equipment

- Hydraulic presses

- Brakes and Braking equipment

- Aircraft – landing gear, flaps, doors

- Aerospace equipment

- Machine blades

- Valve actuators

- Robotic Arms

Benefits of Precision Component Machining for Hydraulic Systems

Precision machining is a key element in designing and manufacturing hydraulic systems. Using advanced CNC machines, precise cuts can be made on various metal components used in these systems. This precision allows for higher pressure ratings and increases the system’s efficiency.

The use of modern manufacturing techniques also helps to reduce production costs in hydraulic component machining by eliminating unnecessary waste materials. By utilizing precision machining within hydraulic systems, manufacturers can create products tailored to every industry’s needs while still providing excellent performance.

FZE Hydraulics Component Machining

Manufacturing complex hydraulic parts and components with high accuracy and repeatability can be challenging. The tight tolerances of these parts make them difficult to produce with traditional manual machining techniques.

Manufacturing complex hydraulic parts and components with high accuracy and repeatability can be challenging. The tight tolerances of these parts make them difficult to produce with traditional manual machining techniques.

However, with FZE’s state-of-the-art Swiss, HMC, VMC, and CNC machining capabilities, our expert team can provide precision parts and components that meet the most stringent specifications.

Our machining services enable us to produce high-quality and precise parts for our customers, thus helping them reduce costs and lead times, improve quality, and increase productivity.

In addition, our secondary services give customers the flexibility to order single-source solutions and simplify their supply chain.

Working with FZE For Component Parts Machining

FZE’s precision equipment consists of CNC HMC’s, VMC’s, Lathes and Swiss machines enabling us to perform a diverse range of machining processes including turning, milling, drilling, boring, tapping, reaming, thread milling, cylindrical grinding, burnishing and polishing. This array of capabilities allows us to manufacture hydraulic parts and components for industries ranging from construction and agriculture to marine, aerospace, automotive and trucking.

Our investment in the latest software tools and machining equipment means that we can meet many hydraulic component needs. Our CAD/CAM manufacturing processes achieves tolerances to 0.0002” or less as required.

Our CNC machines manufacture parts with dimensions ranging from 0.1–15 in diameter, with maximum linear dimensions up to 35 in × 50 in × 120 in in height, length, and width, respectively. We also handle pieces with weights of up to 1,000 lbs.

In hydraulic components, there is little room for error. Our ISO 9001:2015–certified quality-management systems ensure that all our processes produce high-quality products. FZE’s qualified technical staff also manually and visually inspect each element using a variety of coordinate-measuring machines (CMMs) and video monitoring equipment to ensure that all products meet client and industry specifications.

Furthermore, our Lean Black Belt Sigma certification, Lights Out automation, Lean Manufacturing, and Kaizen/5S-based continuous improvement processes ensure that we’re constantly looking for new ways to optimize our processes, meeting demanding turnaround times without compromising final product quality.

If you would like to find out more about our hydraulic component machining capabilities and how we can help with your next project, contact our technical team to request a free quote today!

Contact Us Request For Quote