Among several major applications of lasers in today’s modern world, the use of fiber lasers is one of the most popular and reliable. Used across a huge range of industries that’s only expanded since major technology upgrades hit the sector just under 15 years ago, fiber laser marking carries numerous benefits – what is fiber laser marking, and how does it add value?

At FZE Manufacturing Solutions, we’re proud to offer a huge range of fiber laser material and fiber laser marking services to clients across a wide swath of industries and applications. Here’s a primer on what fiber laser marking is, some of its most common benefits and applications, and why it’s become such a popular option for marking needs.

Fiber Laser Marking Basics

For those just learning about this process, fiber laser marking involves an impression left on items using a laser machine that extracts concentrated energy from light, converting it into a laser beam. It does this through an f-theta lens, which maintains focus on an entire plane rather than a single spot – leaving distinct, notable marks when passing over a surface.

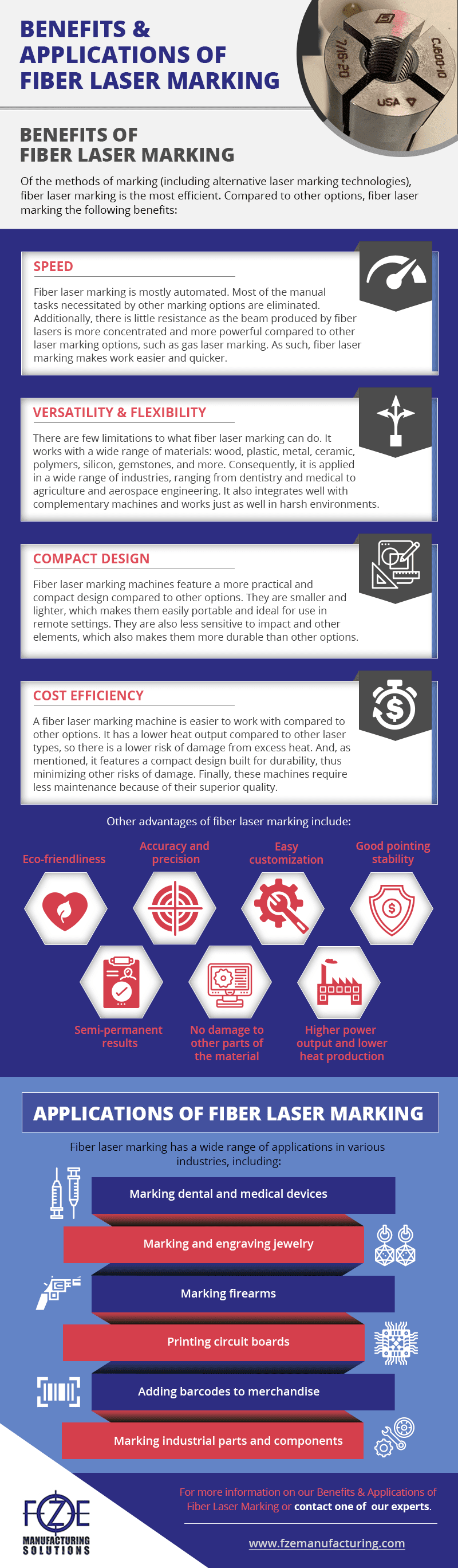

Compared to other forms of laser marking, fiber laser marking is considered the most efficient for some of the reasons below.

Value of Fiber Laser Marking

Fiber laser marking is a highly efficient process, and this is based on several key factors:

Speed

The majority of the fiber laser marking process is automated, meaning that once the initial setup is done, it can run quickly and consistently. This makes it ideal for high-volume production processes. Furthermore, the limited resistance produced by fiber lasers makes it more concentrated and powerful, allowing for faster marking speeds compared to other types of lasers.

Compact Design

Compared to other forms of laser marking, fiber laser marking machines are both smaller and lighter, making them easier to integrate into existing production lines and facilities. Their compact design also means they take up less space, allowing for more flexibility in layout and placement.

Versatility

Fiber laser marking machines can work with a huge range of fiber laser materials, including plastic, metal, ceramic, polymers, silicon, gemstones and many others. This allows for greater versatility and the ability to mark a variety of products, from industrial components to consumer goods.

Cost Efficiency

Due to their lower heat output, smaller design and limited maintenance needs, fiber laser marking machines are more cost-efficient compared to other types of lasers. They consume less power and require fewer replacement parts, resulting in significant savings for businesses.

Environmental Friendly

Fiber lasers produce minimal waste and emissions, making them an eco-friendly option. They also do not require any consumables such as ink or chemicals, further reducing their environmental impact. For individuals or companies looking to reduce their carbon footprint, fiber laser marking machines are a great choice.

High Levels of Precision and Accuracy

Another major advantage of fiber laser marking machines is their ability to achieve high levels of precision and accuracy. This makes them ideal for applications that require intricate designs or small details, such as medical devices or electronic components.

Customization

Because fiber laser marking machines use a computer-controlled process, they offer a high level of customization. This allows for unique designs or personalization on products, making them stand out in the market.

Further benefits include pointing stability, semi-permanent results, higher power output, lower heat production, and absolutely no damage created to other parts of the material during the fiber laser marking process.

Applications and Industries

Fiber laser marking is an incredibly versatile process, with all of the following applications and more:

- Dental and medical devices

- Firearms

- Circuit board printing

- Marking or engraving jewelry

- Barcodes for merchandise

- Industrial component marking

Fiber laser materials are found across dental, medical, electronics, aerospace, automotive, additive manufacturing and several other industries. Its high precision and speed make it an ideal option for marking on a variety of materials, including metals, plastics, ceramics and more.

Our Laser Marking Services at FZE

When you come to FZE Manufacturing solutions for your fiber laser marking needs, you’ll be working with the top professionals and machinery in the industry. We handle all industrial metal types, including aluminum, bronze, copper, iron, steel and various heat resistant metals like titanium. We can also provide markings for perforated materials, plastics, leather, ceramics and more.

Looking for more information on our services? Contact us today at your convenience to learn more about our state-of-the-art fiber laser marking capabilities.