January 10, 2021

Laser marking is a non-contact, non-subtractive manufacturing process that uses lasers to create semi-permanent or permanent imprints on the surface of objects. Rather than removing material from the object, it adds slight discoloration to small, localized areas of the surface. Compared to other marking techniques, this quality makes it better suited for use on sensitive or small parts. Industry professionals often employ the process to add distinct informational markings on finished parts and products, such as identification numbers and ratings. The following article provides a comprehensive overview of the laser marking process, including outlining the various types of lasers employed, laser marking methods, benefits, applications, and materials worked. Additionally, it highlights the differences between laser marking and other processes that utilize laser technology and discusses the laser marking capabilities offered at FZE Manufacturing.

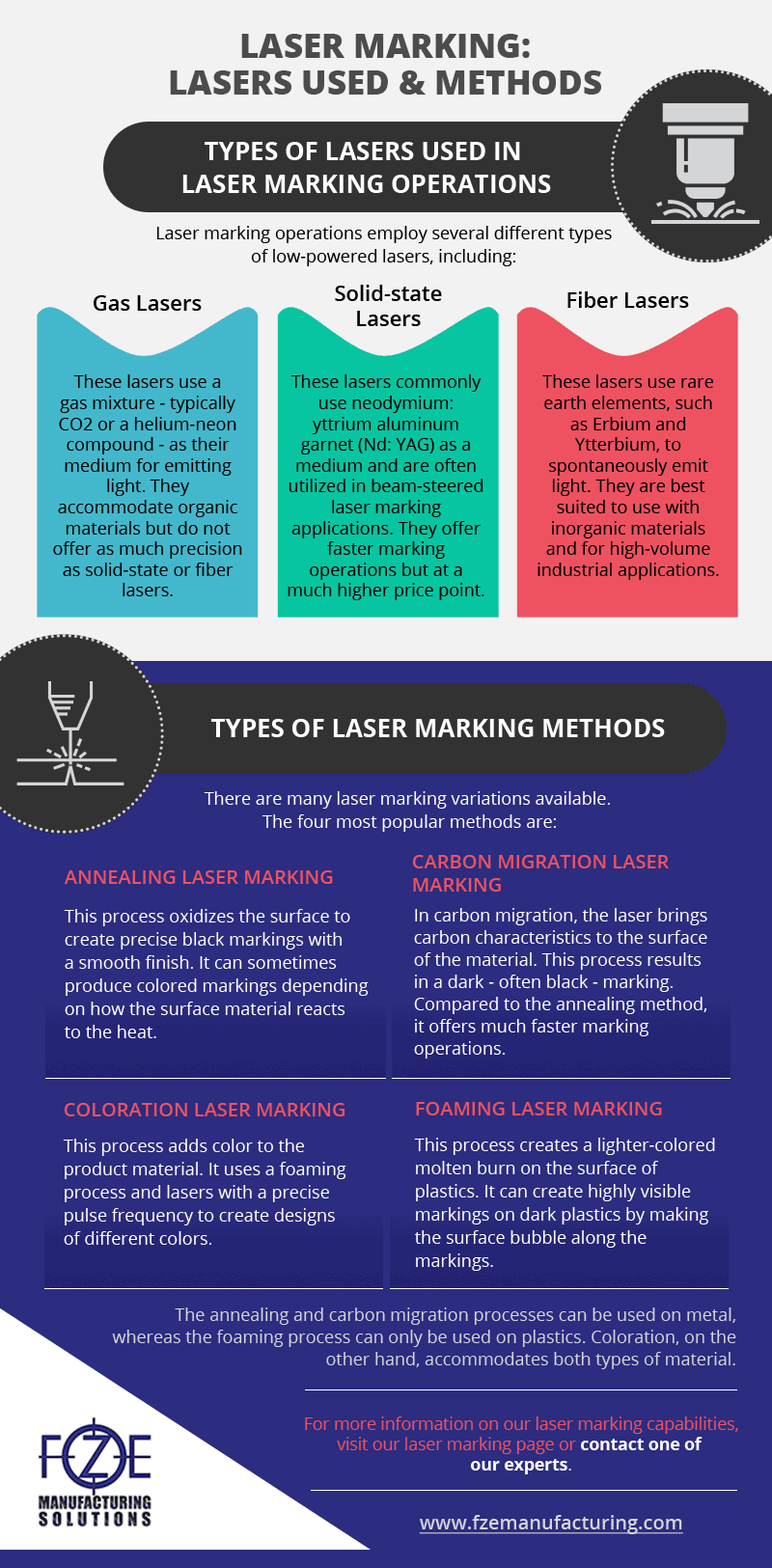

Types of Lasers Used in Laser Marking Operations

Laser marking operations employ several different types of low-powered lasers, including:

- Gas lasers. These lasers use a gas mixture—typically CO2 or a helium-neon compound—as their medium for emitting light. They accommodate organic materials but do not offer as much precision as solid-state or fiber lasers.

- Solid-state lasers. These lasers commonly use neodymium: yttrium aluminum garnet (Nd: YAG) as a medium and are often utilized in beam-steered laser marking applications. They offer faster marking operations but at a much higher price point.

- Fiber lasers. These lasers use rare earth elements, such as Erbium and Ytterbium, to spontaneously emit light. They are best suited to use with inorganic materials and for high-volume industrial applications.

Types of Laser Marking Methods

There are many laser marking variations available. The four most popular methods are:

- 1. Annealing laser marking. This process oxidizes the surface to create precise black markings with a smooth finish. It can sometimes produce colored markings depending on how the surface material reacts to the heat.

- 2. Carbon migration laser marking. In carbon migration, the laser brings carbon characteristics to the surface of the material. This process results in a dark—often black—marking. Compared to the annealing method, it offers much faster marking operations.

- 3. Coloration laser marking. This process adds color to the product material. It uses a foaming process and lasers with a precise pulse frequency to create designs of different colors.

- 4. Foaming laser marking. This process creates a lighter-colored molten burn on the surface of plastics. It can create highly visible markings on dark plastics by making the surface bubble along the markings.

The annealing and carbon migration processes can be used on metal, whereas the foaming process can only be used on plastics. Coloration, on the other hand, accommodates both types of material.

Benefits of Laser Marking

Compared to other marking techniques, laser marking offers many advantages, such as:

- Smaller environment footprint. Laser marking doesn’t use excessive materials or chemicals, making it a greener alternative to other part and product labeling and marking processes.

- Greater durability. Since the laser marks are etched or burned onto the substrate, they can’t be washed off accidentally. The marks are also resistant to solvents.

- Broader versatility. Companies can choose whether the laser markings are permanent or semi-permanent depending on the nature of the information. For example, safety rating information can be permanently marked onto products, while decorative elements can be semi-permanent. Additionally, the process can be used on a variety of substrates, ranging from metals and alloys to plastics, fabrics, and paper, for marking many different designs.

- Lower levels of surface damage. Aside from the burned or chemically altered markings themselves, the laser marking process doesn’t cause any physical changes in the substrate. It also won’t subtract material from the object.

- Faster operations. The laser technology employed allows for quick generation of markings, making the laser marking process well-suited for high-volume orders.

- Higher precision and accuracy. The laser marking process is precise, accurate, and can handle fine detailing requirements.

All of these qualities translate into significant benefits for companies that choose laser marking over other processes. Unlike alternative engraving or cutting methods, laser marking won’t remove material from the objects. It also offers more flexibility than etching and engraving processes, both in terms of the substrates that can be used and the permanence of the marks.

Applications for Laser Marking

The laser marking process finds application in a wide of industries, including in the following:

- Aerospace. The aerospace industry employs a variety of critical equipment that requires a clear indication of safety information and ratings. Permanent laser marks offer a solution that won’t wear off due to extreme conditions or wear.

- Agriculture and Dairy. Industry professionals in the agricultural industry use a variety of marking and branding processes on their products. The markings they make facilitate the tracking of goods during production and processing stages and prepare finished products for retail.

- Automotive. In automotive facilities, fiberglass and metal parts need to be uniquely identifiable. Laser markings serve as a method of marking them with serial numbers that won’t damage the substrates or affect their structural integrity.

- Biomedical and Biopharmaceutical. In these industries, it’s important to have very clear markings on sensitive or potentially hazardous products that won’t alter their nature or performance.

- DOT/DOD/DO. Laser markings can help label, track, and organize large quantities of material that are distributed around the world.

- Electronics. Laser markings allow for clear identification of critical parts and components without altering or interfering with their finely tuned operation or performance.

- Firefighting and Safety Equipment. Safety equipment is required to indicate the manufacturer’s information, ratings and regulations, warnings, user instructions, and other important product data. The laser marking process ensures this information remains clearly marked to ensure the safety of rescue personnel and rescuees.

- Heavy Machinery and Hydraulics. Industrial equipment is often subjected to harsh operational and environmental conditions that cause wear. Laser markings can withstand these conditions much better than stickers and other additive labeling methods.

- Medical. Laser marks distinctly identify medical equipment without changing the item or creating a surface texture that increases the risk of corrosion or contamination.

- Military and Defense. Laser marks facilitate the tracking of equipment and components shipments.

- Oil and Gas. Oil and gas processing operations are tough on equipment. Permanent laser marks can withstand solvents, high temperatures, and other adverse environmental factors.

- Professional Turf and Lawn Care. In the landscaping industry, laser marks are used to identify everything from equipment to rolls of sod.

- Recreational Marine. Saltwater is highly corrosive. Laser markings can withstand both saltwater and freshwater environments.

The above industries, among others, commonly use the laser marking process for the following:

- Asset tracking. Companies can scan laser-marked barcodes at every stop along their supply chain to track the movement of goods from one location to the next.

- Branding. Both semi-permanent and permanent markings designs make products recognizable and can improve their aesthetic quality, making them more attractive to consumers.

- Part and product identification. The laser marking process can be used to indicate unique serial numbers, model names, and more on finished products for identification purposes.

- Security. Permanent marks on sensitive materials allow companies to identify and recover goods in the event of theft.

- Tracing. End-users with laser-marked equipment can trace it back to manufacturers or service providers for repair and maintenance operations.

Materials Worked in Laser Marking Operations

Laser marking accommodates a variety of materials, including:

- Metals such as aluminum, brass, bronze, copper, steel, and stainless steel

- Plastics such as ABS, polystyrene, and PVC

- Inorganics such as glass, gemstones, and stone

- Organics such as leather, paper, and

Laser Marking vs. Laser Engraving/Etching vs. Laser Cleaning

Many processes employ laser technology in their operations. In addition to laser marking, this group includes laser engraving, laser etching, and laser cleaning. While they may use similar equipment, the function and end result of these processes vary greatly.

Both laser engraving and laser etching differ from laser marking in regard to their effect on the surface of the material. While the laser marking process simply discolors the surface to add the desired markings, the laser engraving and laser etching processes remove material to do the same. In laser engraving, a high-powered laser vaporizes localized areas of the surface, creating a slight cavity. In laser engraving, the laser significantly heats the surface, causing it to melt and produce a raised mark.

All three of these processes also differ from laser cleaning. Laser cleaning operations use lasers to “burn” away contaminants such as dirt, grease, or oil from a surface without risking any damage to the surface itself. The process is used as an alternative to polishing and abrasive cleaning methods such as sandblasting.

Laser Marking Services at FZE Manufacturing

FZE Manufacturing is a full-service machining and manufacturing company that offers high-quality laser marking services. Our facility is equipped with gas laser, solid-state laser, and fiber laser technology to accommodate a wide range of laser marking needs. We commonly produce the following markings on customer parts and products:

- Part identification numbers

- Brand names

- Traceability lots

- Production dates

- Serial numbers

For more information on our laser marking capabilities, visit our laser marking page or contact one of our experts. To partner with us on your next project, request a quote today.